Enhancing Durability at LAX: The Role of Vetrofluid in New Runway Installations

2022/2023 Los Angeles International Airport (LAX) saw the installation of new runways as part of a major upgrade to its infrastructure. To ensure the longevity and performance of these new runways, the Federal Aviation Administration (FAA) recommended the use of Vetrofluid, an advanced curing agent and deep-penetrating sealer. This single-treatment solution was applied to the freshly cast concrete, providing unparalleled protection against the harsh conditions that runways endure.

Application of Vetrofluid

Following FAA guidelines, Vetrofluid was sprayed onto the freshly set concrete shortly after casting. The application process included three coats on the main runways and two coats on the taxiways, ensuring comprehensive coverage and maximum effectiveness.

1. Triple Application on Main Runways:

The main runways at LAX were treated with three layers of Vetrofluid. This thorough application process ensures deep penetration, creating a robust barrier that protects the concrete from various environmental and operational stresses.

2. Double Application on Taxiways:

Taxiways, which experience less stress than main runways, were treated with two layers of Vetrofluid. This provides ample protection while optimizing resource use.

Benefits of Vetrofluid Treatment

Protection from Freezing Cycles and Fuel Contamination:

Vetrofluid’s deep-penetrating formula creates a strong internal barrier within the concrete, effectively protecting it from freezing and thawing cycles, which can cause significant damage. Additionally, it prevents fuel and other contaminants from seeping into the concrete, preserving its integrity and extending its lifespan.

Maintaining Runway Friction:

One of the critical factors for runway performance is maintaining the appropriate level of friction for landing planes. Vetrofluid does not alter the surface friction of the concrete, ensuring safe landings and takeoffs without compromising the grip needed for aircraft operations.

Reduction in Rubber Removal Costs:

Rubber buildup from aircraft wheels is a common issue on runways, requiring regular and costly cleaning. Vetrofluid prevents rubber from penetrating deeply into the concrete surface, making it easier to remove. This can lead to savings of up to 40% in rubber removal costs, significantly reducing maintenance expenses.

Longevity and Durability:

By penetrating deep into the concrete, Vetrofluid enhances the durability of the runways, providing long-lasting protection against wear and tear. This results in fewer repairs and less frequent maintenance, ensuring that the runways remain in optimal condition for a longer period.

Conclusion

The application of Vetrofluid on the new runways at LAX represents a significant advancement in concrete protection and maintenance. By following FAA recommendations and using this innovative product, LAX has ensured that its runways are well-protected against environmental and operational challenges. The benefits of Vetrofluid, from enhanced durability to reduced maintenance costs, demonstrate its value as a vital component in modern airport infrastructure management.

For more information on how Vetrofluid can enhance the performance and longevity of concrete in various applications, visit our website and explore our range of innovative solutions designed to meet the highest standards of quality and sustainability.

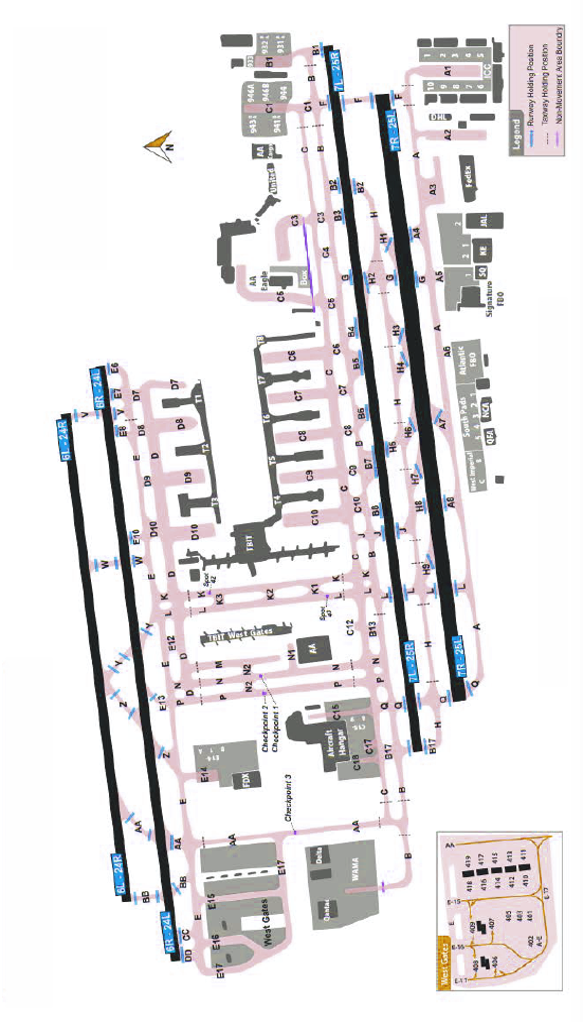

*Note: The images provided illustrate the application process and the condition of the runways post-treatment, highlighting the effectiveness of Vetrofluid in protecting and maintaining concrete surfaces.*