Protecting Concrete in Biogas Plants with Vetrofluid

In the world of renewable energy, biogas plants stand out as a crucial component for sustainable energy production. These facilities convert organic waste into valuable biogas, reducing greenhouse gas emissions and contributing to a circular economy. However, the harsh and acidic environments within biogas plants pose significant challenges to the longevity of concrete structures. This case study highlights the importance of protecting concrete with Vetrofluid and the benefits it brings to the overall operation and maintenance of biogas plants

The Challenge

Concrete structures in biogas plants are exposed to highly acidic conditions and aggressive chemicals produced during the digestion process. This constant exposure can lead to rapid deterioration of the concrete, compromising the structural integrity and safety of the plant. Without proper protection, the concrete requires frequent repairs, resulting in increased maintenance costs and potential operational disruptions.

The Solution: Vetrofluid

To address these challenges, the biogas plant in question chose Ecobeton's Vetrofluid for its exceptional protective properties. Vetrofluid is an advanced waterproofing solution that penetrates deep into the concrete, up to 40mm, creating a robust barrier against acids and chemicals. Here’s how Vetrofluid was applied to ensure long-lasting protection and sustainability:

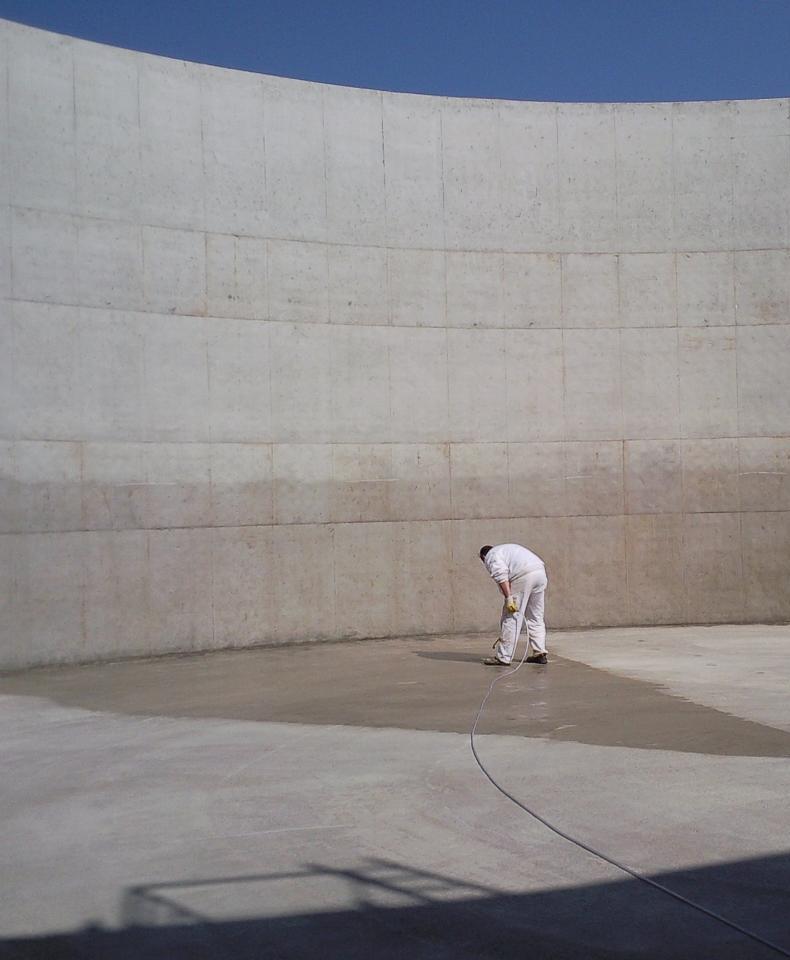

1. Surface Cleaning and Preparation:

The first step was thoroughly cleaning the concrete surfaces to remove any contaminants. This was done using Ecobeton's Degreaser, which effectively flushed out oils and other residues, restoring the concrete's alkali environment.

2. Applying Vetrofluid:

After cleaning, Vetrofluid was sprayed onto the concrete surfaces. Its deep-penetrating formula ensured that the protective barrier extended well below the surface, providing comprehensive protection against acidic attacks and chemical exposure. For extra protection, Vetrofluid was applied 3 times, to fully infuse concrete and fill all the pores up to 40mm depth.

3. Sealing and Protection:

Once applied, Vetrofluid formed a durable matrix within the concrete, preventing future penetration of acids and harsh substances. This protective layer not only extended the lifespan of the concrete but also reduced the need for frequent repairs and maintenance.

Benefits of Using Vetrofluid

Long-lasting Protection:

Vetrofluid’s deep penetration and robust barrier provide long-term protection, significantly extending the life of concrete structures in biogas plants.

Cost Savings:

By reducing the frequency of repairs and maintenance, Vetrofluid helps in lowering the overall operational costs, ensuring better financial returns on investment.

Environmental Impact:

Protecting biogas plants with Vetrofluid supports environmental sustainability by ensuring the efficient operation of facilities that convert waste into renewable energy, thus reducing carbon emissions.

Sustainability Commitment:

Ecobeton's Vetrofluid aligns with the company’s commitment to sustainability, providing eco-friendly solutions that enhance the durability of concrete while respecting the environment.

Conclusion

Protecting concrete in biogas plants is crucial for maintaining operational efficiency and safety. Ecobeton's Vetrofluid offers an unparalleled solution to these challenges, providing long-lasting and effective protection against acidic and harsh environments. By choosing Vetrofluid, biogas plant operators can ensure the longevity of their infrastructure, reduce maintenance costs, and support sustainable energy production.

For more information on Vetrofluid and other innovative concrete protection solutions, visit our website and discover how Ecobeton can help you achieve your maintenance and sustainability goals.

---

*Note: The images provided illustrate the condition of the concrete before and after the application of Vetrofluid, highlighting its effectiveness in protecting and enhancing the durability of concrete surfaces in biogas plants.*